Products

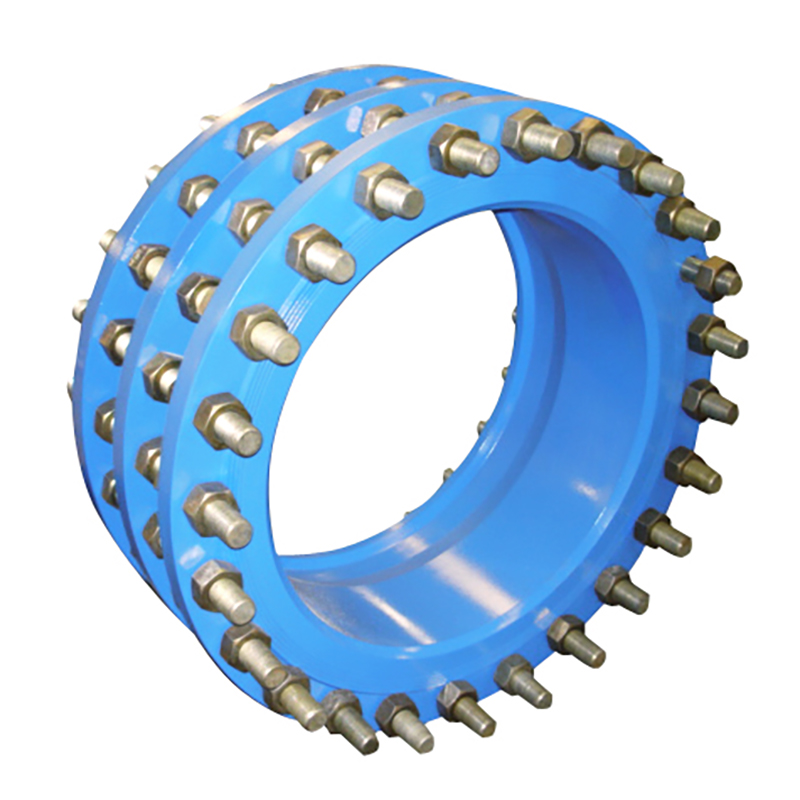

Dismantling joints

Brief description:

Size range: DN50 to DN4000

Pressure range: PN6, PN10, PN16, PN25, PN40 and PN64, Class 150 & Class 300, or more high pressure to be designed specifically.

Suitable medium: water, sea water, gas, oil , ow-corrosive liquid,and ect.

Suitable temp. :-20 to 100℃ degree

Flange and drilling acc.to : ISO7005-2,EN1092-2/-1, ANSI B16,5,ANSI B16.47, AWWA C207 and etc.

Coating: fusion bonded epoxy coating, min. thickness 300 microns

Pressure test acc.to: EN12266-1, ISO5208

Leakage rate: Class A (Zero leakage) in both direction, 100% testing before delivery

Product Description

Main parts material list:

Flange spigot: ductile cast iron, GGG40/50, QT450-10, carbon steel, stainless steel and etc.

Flange body: ductile cast iron, GGG40/50, QT450-10, carbon steel, stainless steel and etc.

Retainer: ductile cast iron, GGG40/50, QT450-10, carbon steel, stainless steel and etc.

Gasket: NBR/EPDM

Tie rods: galvanized steel, grade 4.8,6.8 or 8.8, or with Dacroment, SS304, SS316, duplex steel and other stainless steel, other particular material available as request.

Coating: fusion bonded epoxy coating, min. thickness 300 microns

Package: plywood cases, suitable for shipment by sea, air, or train, pallets for over sizes.

Production description:

1.End connection: double flanges

2.The overall length of the connection can be adjusted, there is a certain amount of expansion. Generally, the design maximum expansion is 50mm.

3.They can replace the double flanges straight pipe, during repairs, repairing the original damaged pipe fittings or connecting new pipes, and the adjustable length characteristics make them more convenient than flange pipes in the application of construction and installation. They are usually connected adjacent to the valve.

4.The bolts * nuts can be directly used for connecting the flange in the pipeline.

5.At the same time, we can also supply half set of bolts, that is, bolts with 50% bolt holes.

It belongs to our new design, which reduce the weight and cost, are more competitive.

The function and principle:

The function of the telescopic device is to connect pumps, valves and pipes, and make compensation for them.

The pipe compensator can be extended axially within a certain range, and can also overcome the offset caused by different pipe axis at a certain Angle.

It greatly facilitates the installation and removal of valves and pipes. It can be freely extended among the permitted pipe extensions. Once it exceeds its expansion, it will exert limits to ensure safe operation of the pipe.

The telescopic device has a multi – direction displacement effect during pipeline operation. The pipes operate due to thermal expansion and contraction, and the subsidence and forces of the crust produce important scaling compensation effects.

The advantages:

1, It can prevent the impact of vibration on the pipeline. Because there is a certain amount of displacement in the telescopic device, it can have a protective effect on the pipeline during vibration.

2, It is conducive to the installation and replacement of pump and valves. There is an interval between the expansion device body and the expansion device, which can be easily adjusted according to the installation size in the process of installation and maintenance.

3, It has a certain buffer effect on the axial, transverse and angular thermal deformation.

The product has a lot of regulating effect on the expansion and contraction caused by the temperature difference in the long pipeline transmission.

Installation:

It designed to provide longitudinal adjustment (up to 50mm) in flanged systems. It provides a simple method for the installation and removal of flanged products by adjusting the distance between two flanged products and turning round.

The installation is also simple and only use a torque wrench to tighten the high strength steel or stainless-steel connecting bolts.

It can be quickly disassembled and very convenient for the repair & maintenance of the valves, pumps or instrumentation.

It simplifies the time required for maintenance and modification in future plumbing and reduces downtime for the entire pipeline project.

Subscribe Now

An unmatched level of quality and serviceWe provide professional customized services for groups and individualsWe optimize our service by nsuring the lowest price.